METAL FABRICATION & ASSEMBLY SERVICES

Laser Cutting, Metal Forming, and Electronic Component Assembly with Engineering Support

AS9100 & ISO9001

AirFixture Sheet Metal Lab

AMADA Fiber Laser Cutting

Experience unmatched accuracy and speed with our state-of-the-art Amada fiber laser cutting systems. We cut a wide range of metals, including stainless steel, aluminum, mild steel and copper, bronze, and brass with exceptional precision and minimal heat distortion.

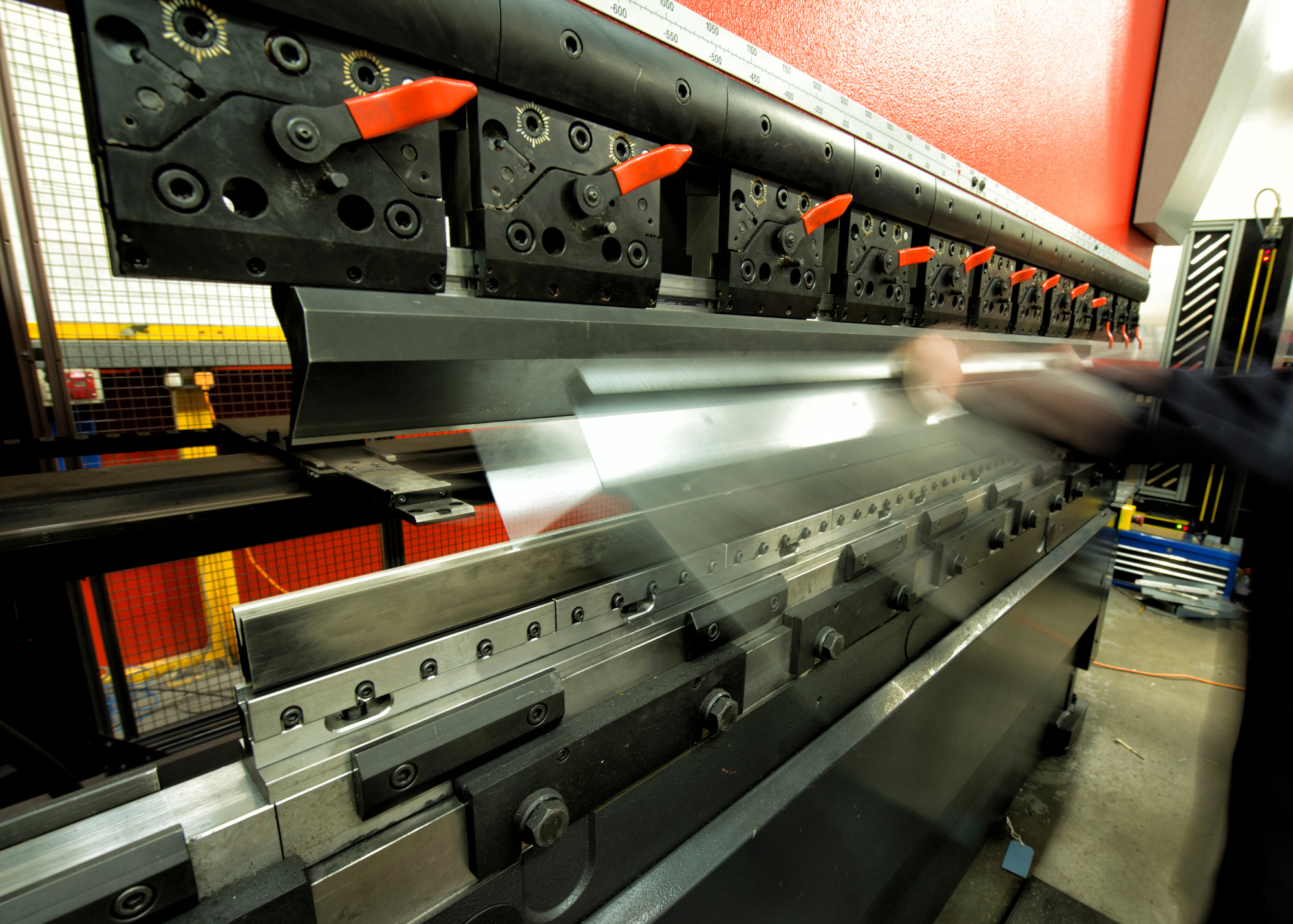

CNC Press Brake Forming

Bend it like a pro! Our CNC press brake delivers consistent and accurate bends on a variety of materials and thicknesses. We specialize in complex bends and intricate shapes to meet your exact specifications.

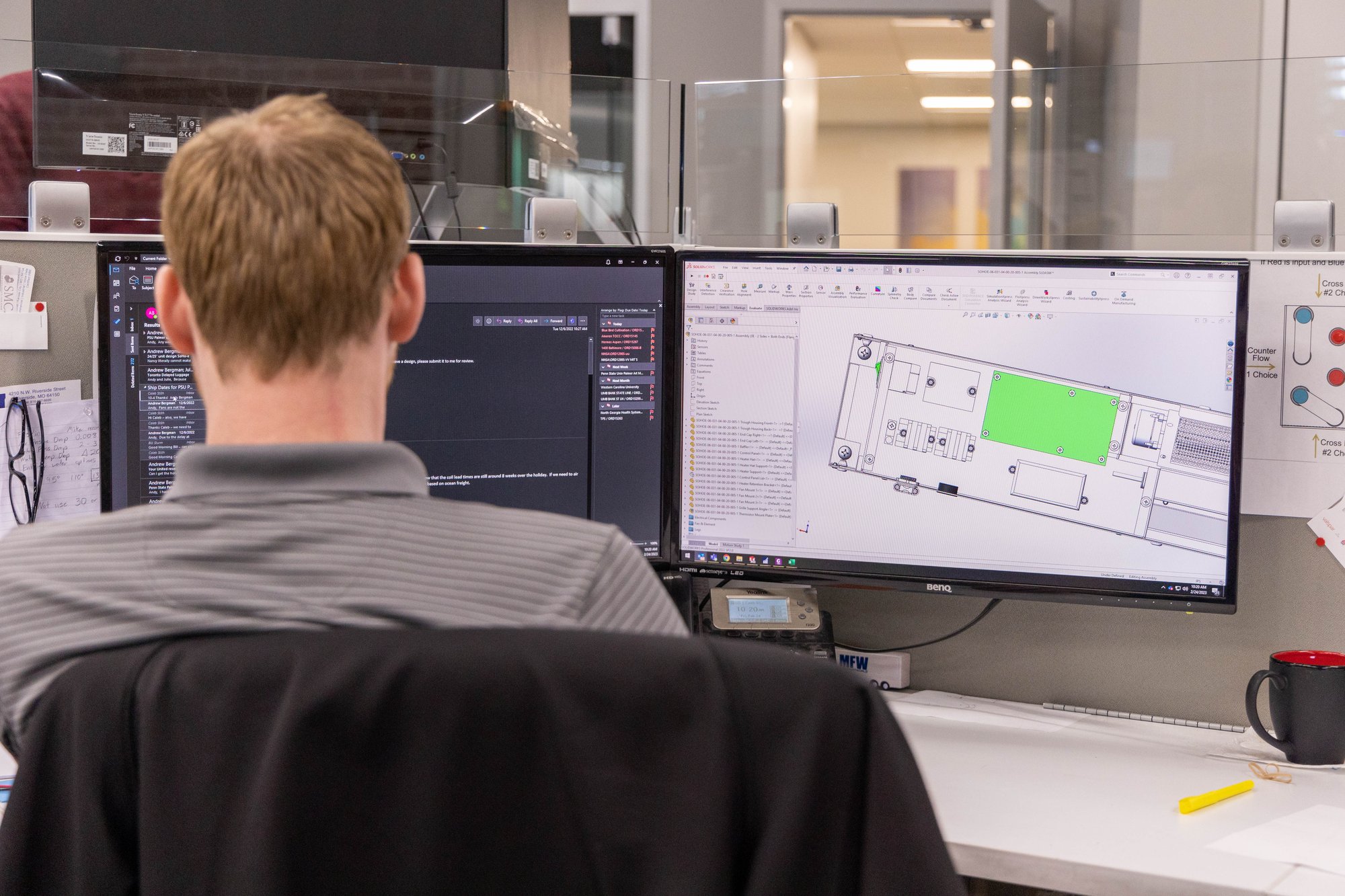

Engineering and Design

AirFixture has a team of 10 dedicated engineers who are constantly working on developing solutions for our clients. We have the modern technology to make parts but our focus is building solutions that keep your production moving.

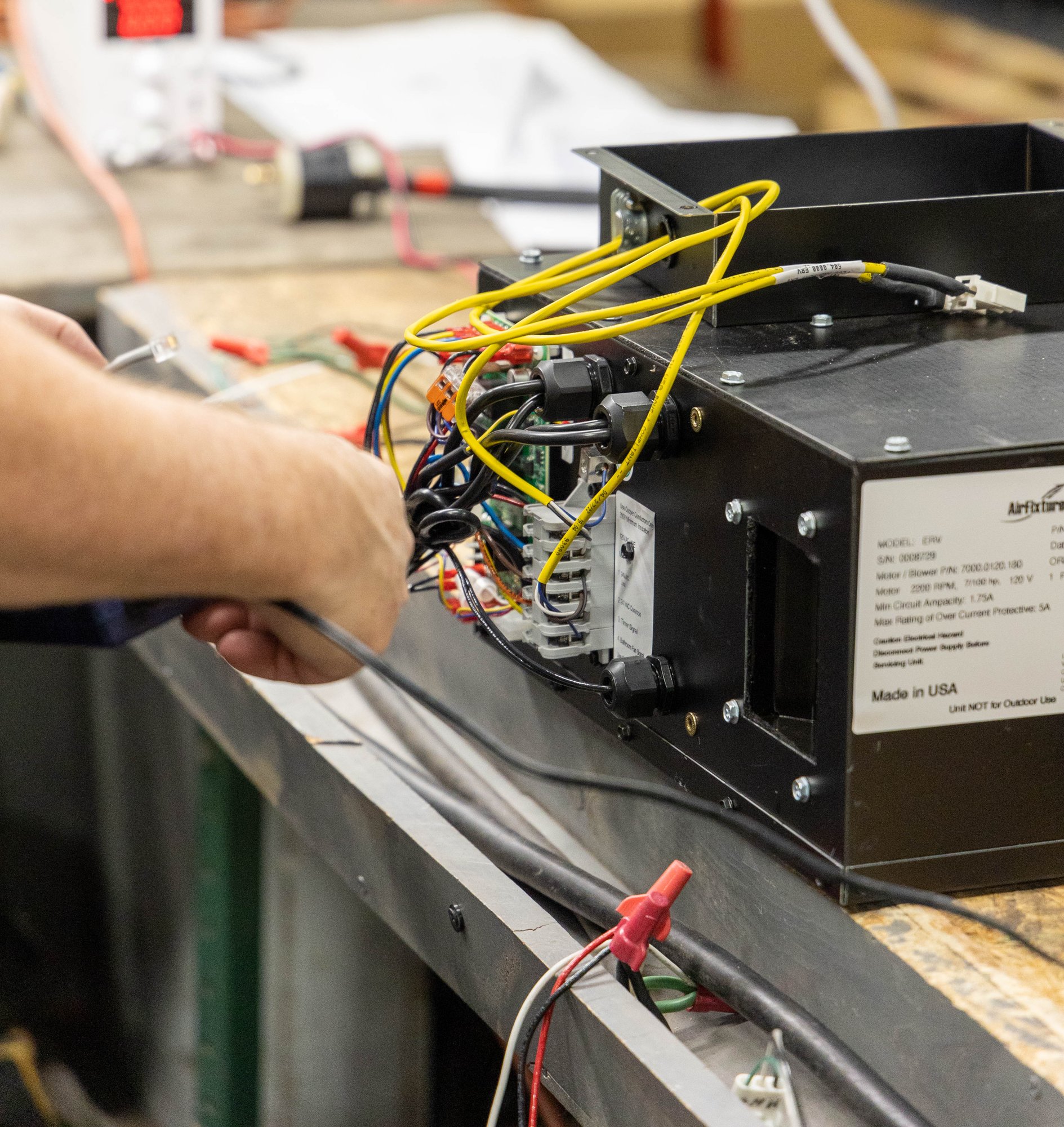

Assembly and Testing

From simple to complex, we provide reliable and efficient assembly and electronic testing services. Our skilled technicians assemble your components and ensure your finished product works as intended.

Rapid Prototyping Services

Bring your ideas to life with our rapid prototyping services, including 3D printing. We can produce prototypes from your designs. allowing you to test and refine your concepts before full-scale production.

Offshore Manufacturing

With over 40+ years of combined experience in manufacturing finished metal products, our offshore manufacturing solutions are mature and equipped to drive costs down while ensuring that you have a point of contact and a building here in Kansas City.

How to Learn More

If you have any further questions, please don't hesitate to contact us. We're here to help!

FAQS

-

What materials can be laser cut?

We can laser-cut a wide range of metals, including stainless steel, aluminum, mild steel, cold rolled steel, galvanized steel, bronze, brass, and copper.

-

What are your size and thickness limits?

Our AMADA 3K fiber laser machine allows us to handle a wide range of sheet metal thicknesses. The thickness limits for most common metals are:

- Carbon Steel up to 1" thick

- Stainless Steel up to 5/8" thick

- Aluminum up to 1/2" thick.

Size and thickness limits vary depending on the material and the specific laser machine being used. Please contact us with your project specifications for precise details.

-

What are the lead times for laser-cutting projects?

Our team aims to work around your schedule whenever possible to ensure your production keeps moving. Generally, lead times depend on the material, order size, and required services. For an accurate estimate, please contact us.

-

What Engineering Capabilities does AirFixture Sheet Metal Lab Offer?

Our engineering team works closely with manufacturers to solve complex fabrication challenges. We provide:

- CAD & CAM Support-Translating designs into production-ready files.

- DFM (Design for Manufacturing) Expertise-Ensuring parts are easy and cost-effective to fabricate.

- Precision Engineering-Fine-turning designs for tight tolerances.

- Assembly & Testing Guidance-Helping integrate fabricated parts into larger systems.

-

Do you offer prototyping services?

Yes, we offer prototyping services. Our engineering team works closely with you to understand your requirements, refine your vision, and quickly develop prototypes. We can also assemble and test the final product, depending on your needs.

-

What details do you need in order to get a quote?

To provide an accurate quote, we need:

- Material type and thickness

- Desired dimensions and quantities

- File format of your design (DXF, DWG, PDF, STEP)

- Any specific finishes or coating required

-

Is there a minimum order amount?

We do not have a strict minimum order amount. However, for small orders, there may be a minimum order charge to cover setup costs. Please contact us for more details.

Contact Our Experts!

Fill out the form today to get more information.