7 High Rise Building Design Considerations

Be it due to different use cases, a myriad of local regulations, and the emergence of industry standards (such as LEED), the ‘standard’ for high rise...

Floor, wall and ceiling mounted to meet your unique project design.

4 min read

Joe Hullebusch : Nov 10, 2020 12:00:00 AM

When you think of modern construction methods, many people think that steel and concrete make the strongest buildings. However, wood - specifically, mass timber - is actually much stronger than either, and it’s making a comeback in the construction industry.

Mass timber is created by combining many pieces of wood to create large support beams that form the structure of a building. With it, builders are framing lighter, stronger structures than ever before in a fraction of the time it takes to raise steel and concrete buildings.

Here are some mass timber construction techniques that builders are using to transform their next projects.

In the past, wood construction was limited to residential buildings and small commercial applications. Mass timber frame construction methods have expanded the type of builds that wood can be used for. With the strength and size of the larger support beams, builders are breaking past the barriers to create massive wooden structures.

In 2019, the University of Arkansas unveiled the largest mass timbered building in the United States, containing an impressive 202,027 square feet of interior space.

But builders aren’t only excited about the added structural strength that wood provides:

Wood isn’t just for residential buildings anymore. New mass timber frame building techniques allow even large commercial buildings to reap the benefits of wood construction.

Mass timber building techniques are different from traditional timber framing. Instead of using two-by-four pieces of wood cut on-site, mass timbers are created and cut in a factory before being shipped to the construction site.

When they arrive, they’re pre-cut and ready to fit together using lap jointing, which is:

All the pieces are then fitted together precisely according to the chosen framing technique.

Below are just a few of the following mass timber frame construction techniques that builders are using to create impressive commercial and residential structures.

Platform systems are when each floor of a structure is framed separately and built on top of one another.

Each floor contains:

This type of construction technique is mostly used for residential buildings with fewer floors.

Balloon systems take a vertical approach to mass timber construction.

Instead of framing one floor at a time, construction timbers are:

Balloon systems are most common in larger industrial or commercial applications because of the height they allow.

Instead of using individual support beams to hold up the floors - like most other construction methods - this technique uses load-bearing walls made of mass timbers as the main structural component (as the name suggests).

What are some key differentiators of massive timber panel wall systems?

Due to the lack of an open floor plan, buildings with massive timber panel wall systems need to have a detailed layout before construction. Once the building is complete, it’s very difficult to change.

Post and beam systems are the opposite of massive timber panel wall systems. Instead of walls, they use huge load-bearing vertical posts that support long horizontal beams.

A significant benefit of this technique:

This construction technique is popular in commercial applications and is gaining popularity in residential constructions because of the floorplan possibilities.

Hybrid systems aren’t restrained to any building material or construction technique. They use wood, concrete, and steel together, taking advantage of the benefits of each. Many hybrid buildings are half steel and half timber construction to benefit from the rigidity of the steel with the strength and aesthetics of wood.

Mass timber construction is excellent for creating large, open commercial and residential buildings, but it does have downsides. One of the most frustrating aspects builders need to overcome is where to put vents for HVAC.

Unlike traditional buildings, mass timber buildings don’t have empty spaces behind walls and above ceilings to hide large vents and air ducts. Any interior HVAC equipment needs to be hidden by additional walls and ceilings, which can be expensive and ruin the open floor plan - or simply be left exposed, which hurts the aesthetics of the wooden structure.

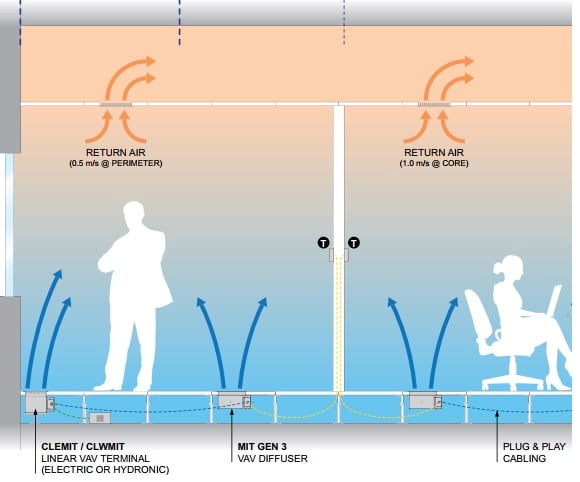

Underfloor air distribution (UFAD) is the best way for mass timber builders to avoid HVAC challenges.

These systems offer significant advantages for builders, including:

Since UFAD systems use many smaller floor diffusers placed all around the space, your HVAC system can run more efficiently, saving money on energy costs while also improving indoor air quality.

Want to learn more about underfloor air distribution to help your mass timber construction project go smoothly? Trust the experts at AirFixture.

We’ve been providing UFAD solutions to businesses and builders around the world for almost 20 years. We work with builders to create customized UFAD solutions to suit your unique project needs - helping construction go smoothly and benefitting building occupants for years to come.

Contact us today for a free consultation and learn how a UFAD system can enhance your building project.

Be it due to different use cases, a myriad of local regulations, and the emergence of industry standards (such as LEED), the ‘standard’ for high rise...

Architects and building designers face difficult decisions when developing a design for a new or retrofitted building. From ceiling heights to...

Casinos rely on their patrons to drive revenue, but it wouldn’t be accurate to restrict the revenue generating potential to just their core business....